Axial Bearing Damage

DISCO SYNCRO SPINDLE

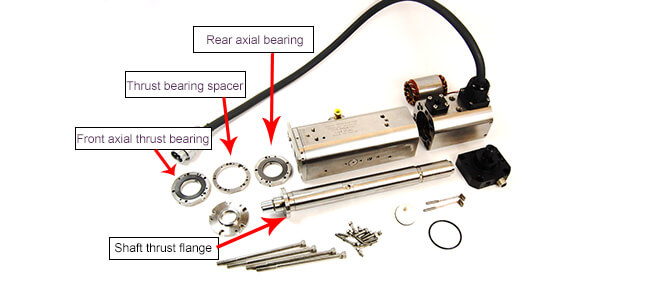

Axial bearing prevent the spindle shaft from moving in and out of the spindle.

Dicing and back grinding spindles use air bearings. To keep the shaft spinning with high precision, both radial and axial (thrust) bearings are required. The axial bearing holds the spinning shaft in the axial direction and resists thrust forces that act along the axis of rotation. HST can repair damaged axial bearings to like new.

Most of the damage we see on axial bearings is the result of contamination in the air supply or internal coolant leakage. But axial bearing damage can also result from contamination migrating past the front labyrinth seal.

Axial bearings typically are located toward the front of the spindle. They are referred to as the front thrust bearing, rear thrust bearing and the shaft thrust flange.

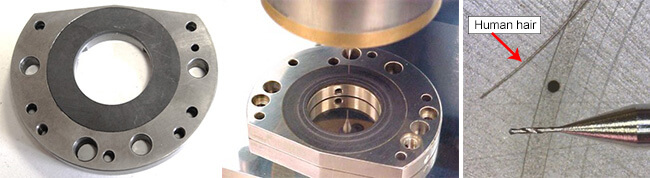

The front axial bearings are often damaged from contamination entering the spindle through the labyrinth seal. If the spindle is not properly setup or maintained, cutting slurry can penetrate the seal and work its way between the front axial bearing and the shaft thrust flange severely damaging both surfaces.

Left Photo: Contamination from cutting slurry wore deep striations on both the shaft thrust flange and the front axial bearing.

Right Photo: This Disco front axial bearing is badly damaged from cutting slurry contamination.

Internal leakage often results in damage to the rear thrust bearing.

Liquid contamination plugged the journal jets and then the air pressure blew the graphite bearing out of the rear thrust housing

How to Repair an Axial Bearing:

Step One: Remove damaged bearing from bearing housing:

Left Photo: Damaged

Axial Bearing.

Middle Photo: Partially removed bearing.

Right Photo: Bearing completely removed and housing prepped for machining.

Step Two: Rough machine bearing material:

Left Photo: Bearing material is turned and cut to size.

Right Photo: Bearing material is bonded to housing.

Final steps:

Left Photo: Preliminary Surface Prep.

Middle Photo: Grooving and Drilling Jets.

Right Photo: Close up of Grove and Jet.

Axial Bearing restored to new and ready to install

The shaft thrust surfaces are also damaged from contamination and must be restored to pristine condition for the spindle to perform like new.

Repairing this thrust flange will reduce the overall thickness.

It is critical that all surfaces involved with the axial bearing systems are perfectly flat, parallel and perpendicular to the axis of rotation. Additionally, the original air gap space must maintained. So when any changes in the shaft axial thrust flange are made because of excessive wear, they must be compensated for with the thrust spacer.

The spacer must be ground flat and parallel. Any changes in the shaft flange dimensions must be compensated for with the spacer.

Shaft thrust surfaces require precision grinding to restore them to like new performance.

Testing the thrust capacity of an axial bearing repair on a Disco dicing spindle

When we repair your dicing spindle or other air bearing spindle performance is tested. We have different test stands and methods to guarantee your spindle will meet our stringent performance criteria.

HST can repair your dicing, back grinding or other air bearing spindle no matter what the damage. All of our air bearing repairs are fully guaranteed.