CMS Brembana Spindle Repair & Rebuild Services

Your CMS Brembana spindle is in expert hands with the factory-trained, Big Plus–certified technicians at High Speed Technologies, Inc. We have repaired dozens of CMS Brembana spindles to original factory performance. Need it fast? We can repair and rebuild your spindle within three days of customer approval, and we offer reduced pricing for longer lead times. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are some common CMS Brembana spindle performance issues that we resolve:

- Noisy or contaminated bearings

- Increased vibration

- Chatter marks

- Blunt force trauma

- Burned stator

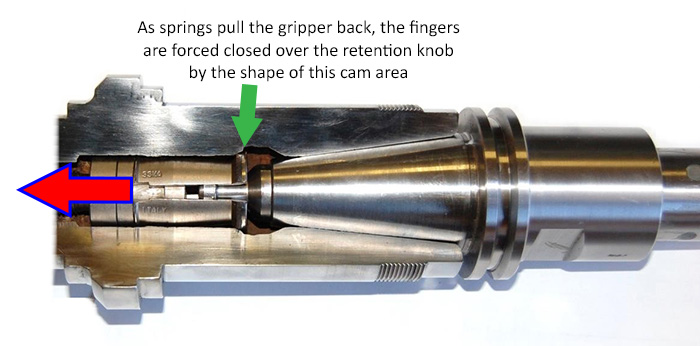

- Fatigued springs

- Poor part finish

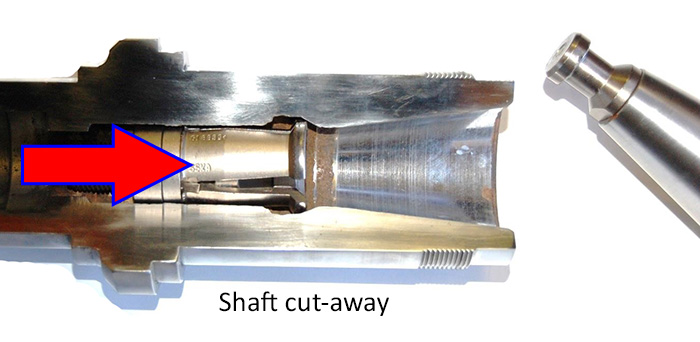

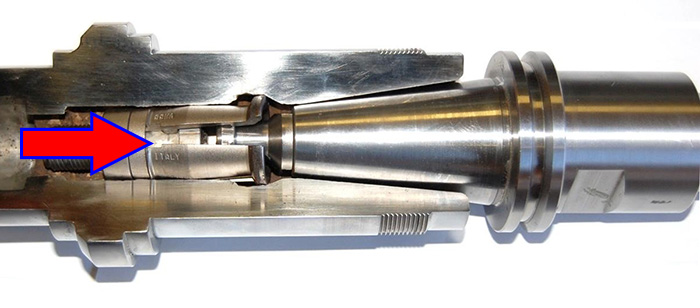

- Failed seal

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will include replacing or restoring all worn drawbar springs, seals and critical surfaces. Then we perform high-speed balancing to eliminate vibration, extend life and improve part quality. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

For expert Mori Seiki or DMG Mori spindle repair, email using the form or call us at 1-603-483-0333 for a quote. We are fast, experienced, and our work is guaranteed.