Mitsubishi Spindle Repair & Rebuild

Your Mitsubishi spindle is in expert hands with the factory-trained technicians at High Speed Technologies, Inc. We have repaired dozens of Mitsubishi spindles to original factory performance. Need it fast? We can repair your spindle within three days of approval. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Your Mitsubishi spindle is in expert hands with the factory-trained technicians at High Speed Technologies, Inc. We have repaired dozens of Mitsubishi spindles to original factory performance. Need it fast? We can repair your spindle within three days of approval. All spindle repairs are backed by a complete warranty and our 30-year reputation of OEM-quality spindle repair.

Here are just some of the common Mitsubishi spindle performance issues that we resolve:

- Noisy bearings

- Contaminated bearings

- Increased vibration

- Poor part finish

- Failed seal

- Shaft end play

- Shaft seized

- Excessive runout at Taper ID

- Dropping Tools

- Low drawbar pull force

- Worn gripper assembly

At HST, we replace all bearings with top name-brand ABEC 7 super-precision spindle bearings. Your spindle repair will minimally include replacing all seals, grinding bearing spacers for proper preload and restoration of damaged shaft surfaces. Then we perform high-speed balancing to eliminate vibration, extend spindle life and improve finish quality on parts. HST has provided the CNC machining community with a high-quality alternative to higher-priced OEM spindle repairs since 1986.

Mitsubishi RD4001129:

Mitsubishi spindle before and after

The above Mitsubishi RD4001129 spindle was removed from a LITZ HITECH machine. It was sent in to us because it was noisy and had begun dropping tools. After removing the drawbar from the spindle we were able to confirm our theory, broken Bellville washers. The gripper was also extremely worn and likely a contributing factor to the tool holding issues our customer had experienced. When we rebuilt the spindle, we replaced the gripper and all springs with new.

Worn Gripper Assembly

Several broken drawbar springs.

At times when a spindle drops a tool or a tool pulls out of the shaft taper; it does some damage on the way out. But not in this case. The runout measured at the taper ID was within specification and the taper angle measured an AT Class 3 on our Stotz certified air gauge. Not too bad for a steep taper such as this.

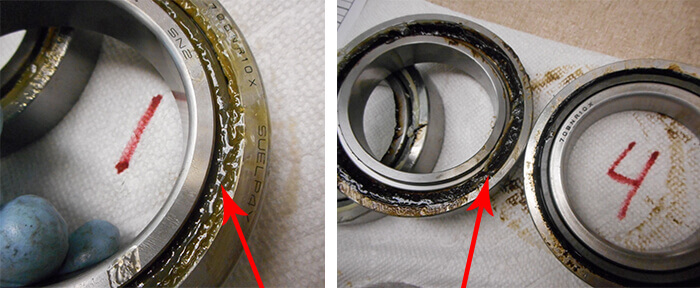

Now for the reason the spindle was “noisy.” Prior to disassembly the bearings did rotate freely but we could definitely hear the excessive noise the customer had noted as a concern. When the bearings were removed from the spindle we could see that they were worn and contaminated with a foreign substance which looked to be oil based. Although the bearings did rotate freely, they would have likely failed catastrophically in short order.

Oil-like contamination observed within each bearing

After replacing all seals and bearings with new top of the line NSK bearings and rebuilding the drawbar, we were ready for testing. Holding a tool would no longer be an issue as the draw force was increased by over 1,000 lbs. And at 15,000 RPM this Mitsubishi RD4001129 spindle once again ran like new! All components, including a detailed report of the repair, are properly and securely packaged for transport back to the customer. This customer was very pleased with their finished product “Package arrived well packaged and in good shape”.

All components of the spindle are packaged nicely for transport

Mitsubishi DM800:

The following Mitsubishi DM800 spindle was sent in to High Speed by a customer out of Canton, OH who manufactures high end medical components. Their main concern was that the spindle was “getting hot.” So they sent the spindle.

The spindle itself is a robust, high speed spindle with a rigid HSK tooling system with ability to do the intricate work that medical manufacturing often demands.

Clamping system.

HSK taper and tooling.

Upon disassembly there were indications that this spindle had been rebuilt by another spindle repair house at some point in the past. The main indicator was the bearings themselves. After consulting the bearing catalog provided by the manufacturer of the bearings and calculating the limiting factor of each bearing, it was clear that the bearings were underrated for the maximum speed of the spindle (24,000 RPM). This was what caused the bearings to deteriorate quickly to the point where they began to overheat.

The critical surfaces on the shaft and within the housing bore were in good overall condition. We replaced the existing bearings with a ceramic hybrid which were rated for well beyond the 24,000 max rpm. We also replaced all 60+ O-rings and rebuilt the drawbar.

Clamping sensors.

Encoder head and target.

All springs were replaced with new.

Assembling this spindle took several hours alone and was only half of the fun. Because this spindle has several electrical components and sensors, there was much testing and fine-tuning to accomplish before we could even begin running it. The clamping sensors had to be adjusted and tested. The encoder gap – which was measured before we dismantled the spindle – was measured, set and verified. And of course the stator was thoroughly checked upon initial evaluation. Then we could finally set the spindle up for test run.

We ran the spindle a variety of speeds for several hours until we reached 24,000 RPM monitoring vitals along the way. In the end the spindle ran excellent at 24,000 RPM. It also ran cool at 75f Degrees. There was no indication of a coolant leak but we pressure checked the coolant circuit to be positive.

Confident that this Mitsubishi DM800 spindle was returned to new condition, it was prepped for shipment and safely returned back to the customer.

Wrapped up and ready to go!

Here at High Speed Technologies we love a happy customer! For expert Mitsubishi spindle repair, please email or call us at 603-483-0333 for a free, no obligation quote. We offer one-year warranty and Quick-Turn-Around. We are fast, experienced and our work is guaranteed!!